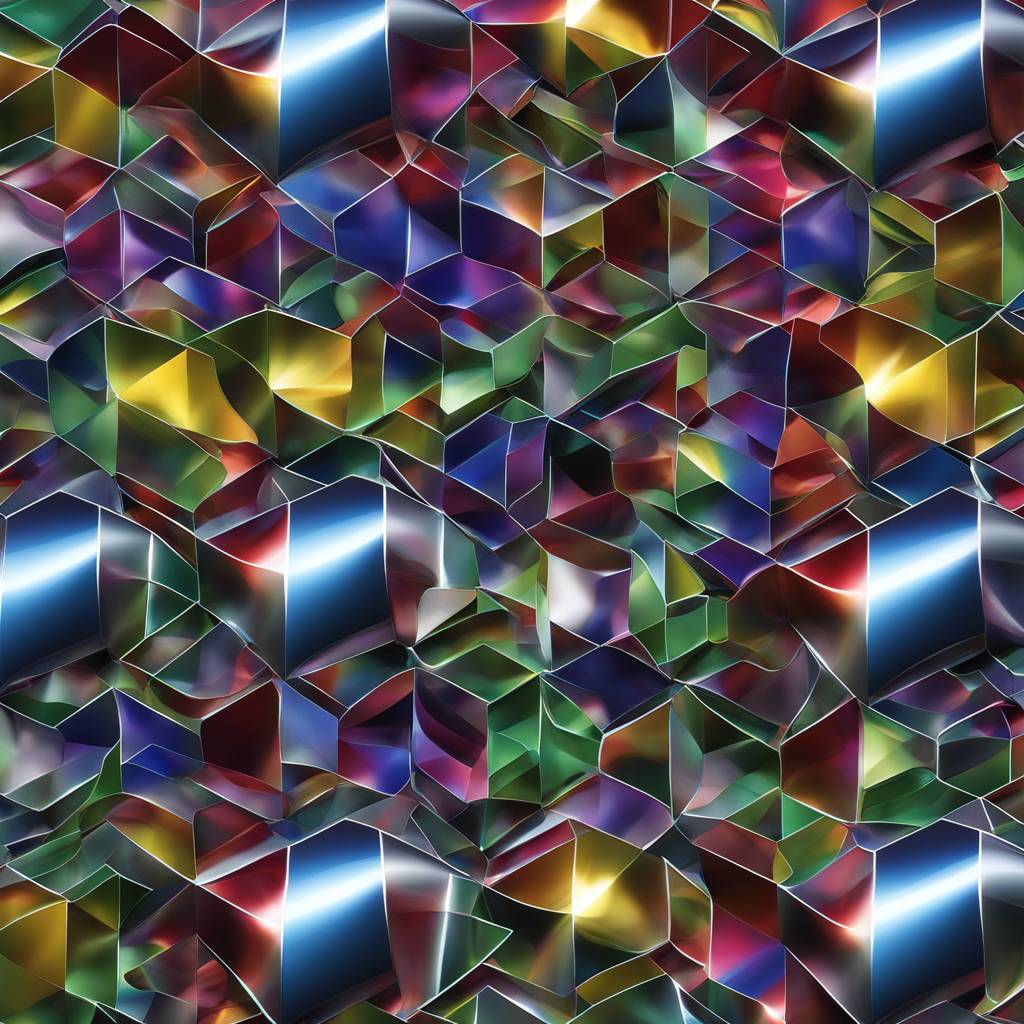

Metalenses are nano-artificial structures that manipulate light and have the potential to revolutionize the optical industry by reducing the size and thickness of traditional optical components. These lenses are particularly effective in the near-infrared region, making them highly valuable for applications such as LiDAR, miniature drones, and blood vessel detectors. However, the high cost of production for metalenses has hindered their commercialization, with even a fingernail-sized metalens costing tens of millions of won to fabricate. Fortunately, recent breakthroughs have shown promise in reducing production costs significantly.

A collaborative research team from POSCO, POSTECH, and Korea University has proposed two innovative methods for mass-producing metalenses and manufacturing them on large surfaces. By employing deep-UV photolithography, the team was able to achieve the mass production of metalenses for the visible light region, showcasing the potential for large-scale production. Additionally, the team developed a material with high refractive index and low loss to address efficiency issues in the infrared region, resulting in the successful creation of a sizable infrared metalens with exceptional light-collecting capability and high resolution.

In another approach, nano imprinting was utilized to print nanostructures using a mold, allowing for the mass production of a metalens with impressive performance characteristics. This metalens exhibited polarization-dependent properties, responding effectively to the direction of light vibration. By integrating a high-resolution imaging system to observe real samples, such as onion epidermis, the team demonstrated the commercial viability of metalenses, overcoming the limitations of traditional one-by-one production processes and reducing production costs by up to 1,000 times.

Professor Junsuk Rho, who led the research, highlighted the significance of achieving precise and rapid production of high-performance metalenses on a wafer-scale, reaching centimeter dimensions. He emphasized the potential for this research to expedite the industrialization of metalenses and advance the development of efficient optical devices and technologies. The research was supported by POSCO’s Industry-Academic Integrated Research Center and various programs from the Ministry of Science and ICT.

Overall, metalenses offer a promising technology for the optical industry, with the potential to enhance various applications such as LiDAR, drones, and medical devices. The recent breakthroughs in mass-producing metalenses and reducing production costs hold great promise for their commercialization and widespread adoption. By utilizing innovative methods such as deep-UV photolithography and nano imprinting, researchers are able to overcome efficiency challenges and create metalenses with impressive performance characteristics, paving the way for the advancement of optical technologies.